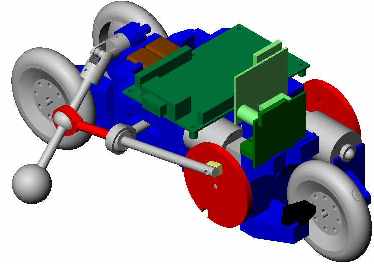

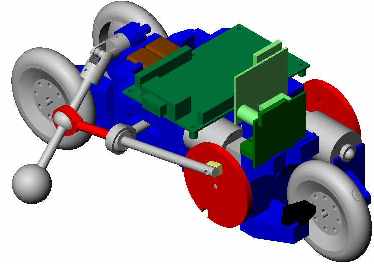

The next step was to track down all of the necessary components and generate a solid model

of the system using SolidWorks. Our design called for two universal joints to anchor the arms, and four gimbels to

move them. We were given two motors for propulsion, but without any data sheets. Additionally, we would require

batteries, two H-bridges, a DSP board, and sensors to complete the system. An isometric view

of the solid model is shown in the header, and a video showing the model in action is given through the link below.

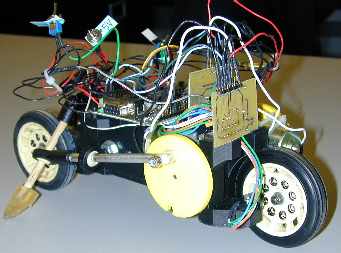

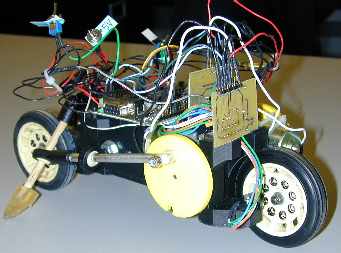

After the solid model was completed, the device was constructed using traditional machining and Fused Deposition Modeling.

In addition, the final solid model was imported into ADAMS to ensure proper function. The video of this simulation

is also available below. Notice the nice airfoil path that the paddle foot follows.

|